Verify correct installation of cable assemblies

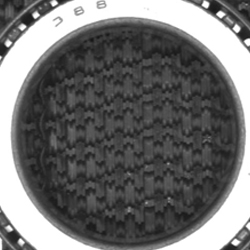

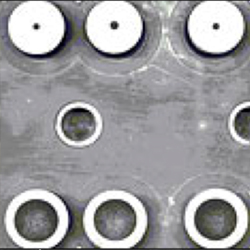

Verify part features, such as bearings, using counting tools

Verify part features, such as bearings, using counting tools

Verify the presence, location, and orientation of sub-assemblies

Could your manufacturing process benefit from vision tasks like these?

Guide robots to pick and install parts on assemblies

Ensure part traceability throughout the product life cycle

Check assembly using color verification tools

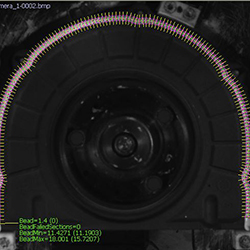

Verify the integrity and uniformity of adhesive beads

Hand-counting piston rings as small as 0.29 - 0.79 mm in width and packaging them in various batch counts, was not only adding to labor costs, but also proving unreliable in the highly competitive automotive sector. A far more reliable answer came in the form of a custom machine vision solution using Teledyne DALSA's Sherlock software.

Read the full article >>